Your cleanroom expert

Alsico High Tech is a global supplier of garments for cleanrooms, clean areas, ESD environments and operating theatres. We develop, produce and supply high quality cleanroom garments, clean area garments and ESD garments to rental companies, end-users and specialised distributors.

production units

family business

per year

per week

More about us

We are part of the Alsico group, specialist in workwear with more than 80 years’ experience. Alsico High Tech started in 1990 as a division of Alsico Belgium but became a separate company in 2011. This was essential to concentrate 100% on its core business: creating and producing cleanroom garments, which protect the product from the workers and not the other way around.

Mission

Our goal is to produce and supply high quality cleanroom garments at a competitive price within an acceptable delay. We want to fully support our customers by providing a wide range of garments and by delivering the best service in terms of quality, delivery and technical support.

We want to be the most trusted cleanroom garment supplier worldwide!

Team

We have an experienced and motivated team. We care about our employees and have a pleasant business culture. All our colleagues work together to achieve the same company goals . This results in greater customer satisfaction. Teamwork divides the tasks and multiplies the success. If you want to go fast, go alone, if you want to go far, go together.

Expertise

Our well-skilled and enthusiastic team puts in a daily effort to meet the changing demands and specifications of our customers. A reliable partnership with both suppliers and customers enables us to ensure that all delivered goods meet the most critical standards and norms. Years of gathering validation data with our pharmaceutical customers has given us a profound knowledge of the challenging requirements of the cleanroom environment.

Custom-Made

We adapt our garments according to our customers’ needs. We have our own cleanroom garment development team and know-how of all standards.

Measuring

Having sales offices in different continents, allows us to have the right patterns for all continents and ensures a correct fit for all.

Fabrics

Large selection of own-developed fabrics and colours for all cleanroom classes.

Flexible

Own, dedicated cleanroom production units in different continents make us flexible in terms of lead times. We offer in-house quick sampling and have full control of the product supply chain.

Our main office is located in Ronse, Belgium. We have sales offices and dedicated cleanroom production plants in Europe, USA, Asia and Africa. We are able to offer a global supply with local service.

Cleanroom

A cleanroom is an environment with a controlled level of contamination such as dust, microbes, vapours and aerosol particles. A cleanroom is defined by the number of particles per cubic meter at a specified particle size.

Cleanrooms are used in almost every industry where particles can harm the manufacturing process or contaminate the product. This includes pharmaceuticals, microelectronics, life sciences, biotechnology, food packaging, electronics, automotive and optical industries. Air filtration and airflow management control the concentration of airborne particles inside the room.

Personnel selected to work in cleanrooms undergo extensive training. They enter and exit the cleanroom through airlocks, air showers and/or gowning rooms, and they are trained to wear special clothing designed to retain pollutants that are naturally generated by skin and the body (skin flakes, hair,..).

Cleanroom garments are designed to minimise or eliminate particle release from the wearer’s undergarments and prevent the cleanroom from contamination. Protection of the product made in the cleanroom is essential.The type of cleanroom garments used should reflect the cleanroom and product specifications.

Alsico High Tech provides cleanroom garments according to the IEST-RP-CC003.4 standard for all cleanroom classes.

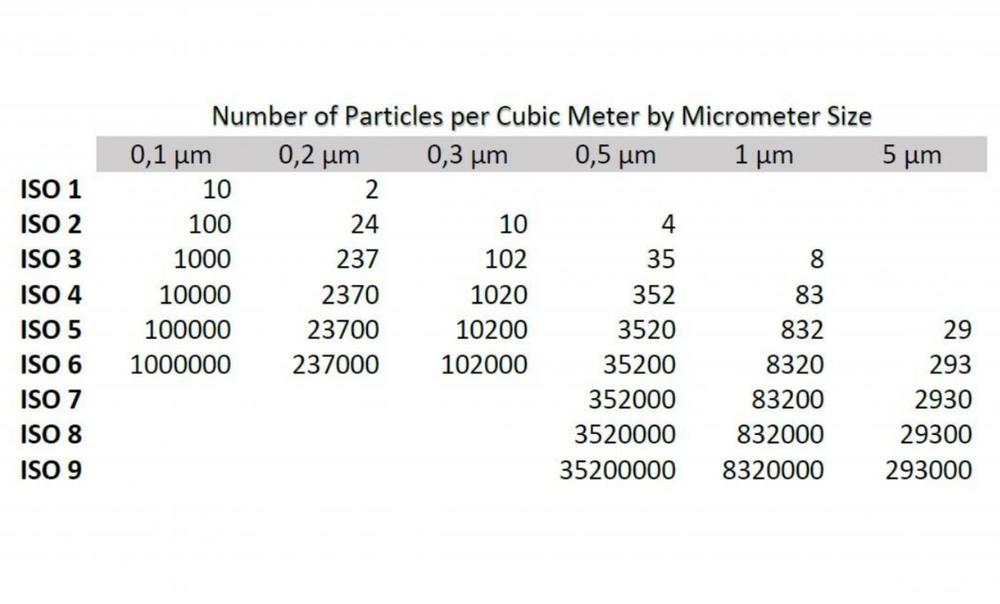

ISO 14644-5 classification

Cleanrooms are classified according to the number and size of particles permitted per volume of air.

ISO 14644-5 : cleanrooms and associate controlled environments : Part 5 – operations

This standard provides the basic requirements for operating and maintaining cleanrooms and associated controlled environments and ranks cleanrooms in ISO classes. The system is rated on the number of airborne particles per m³ and the size of those particles, with 1 being the most hygienic cleanroom environment. The smaller the number, the cleaner the air in the room.

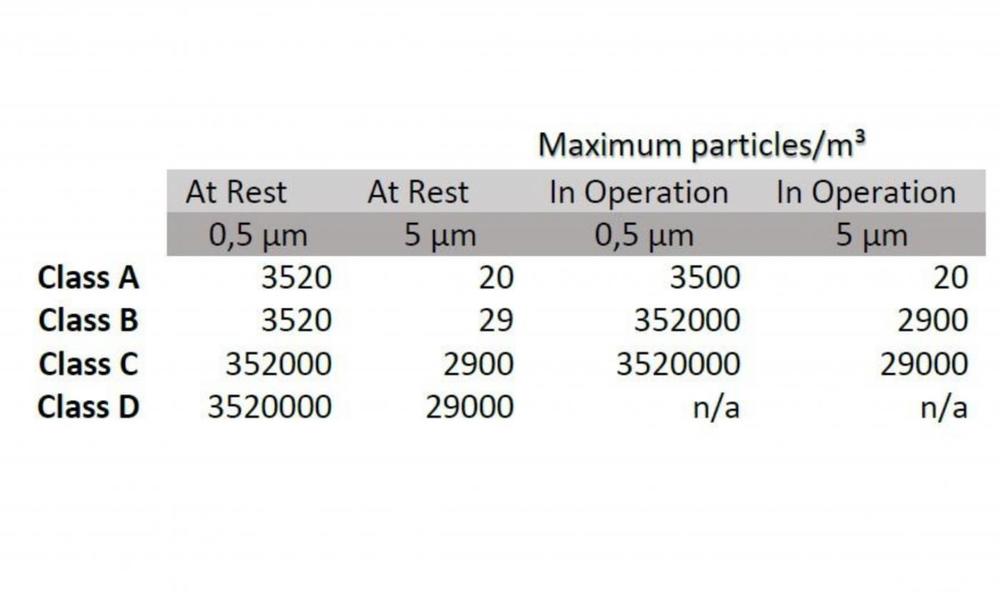

GMP EU classification

The maximum number of airborne particles permitted per m³ ≥ the tabulated size is used to classify the cleanroom into class A to D.

Testing

The most common tests performed on woven fabrics and garments for cleanrooms are:

- Helmke Drum test or ASTM F51

- Tear Strength (Elmendorf) (ASTM D2261)

- BODY – BOX

- Pore size ISO 9237

- Particle filtration efficiency

- Microbial penetration test EN ISO 22612

- Linting test (Gelboflex) / Quick linting tester

- Tensile Strength (ASTM D 5034-58035)

- Air permeability (ISO 9237)

- Water vapor permeability BS 7209

- Weight (ASTM E96)

- Electrostatic properties

Sterilising

Cleanroom garments and most important, all components of this one particular garment must be compatible with the validated sterilisation method:

- ETO

- STEAMSTERILISATION

- 20 min à 121 ° C (2050 mbar )

- 4 min à 134 ° C (3050 mbar )

- BETA RADIATION

- GAMMARADIATION (25 kGy per cycle)

In-house cleanroom lab

ISO 9 lab for testing with build-in Bodybox (ISO 5-6 cleanroom, ISO 7-8 changing room)

- HSH

- Filtration efficiency

- Colour testing

- Washing & drying

- Weight

- Helmke drum

- Bodybox

- ...